2024-05-22

Metal powder water atomization is a process that uses high-pressure water jets to break down a stream of molten metal to produce metal powder. The molten metal is melted in a furnace and then poured through a small-diameter nozzle, where it encounters a high-speed water jet. The water jet breaks the metal stream into small droplets, which quickly solidify into spherical metal powder particles due to the rapid cooling effect of the water.

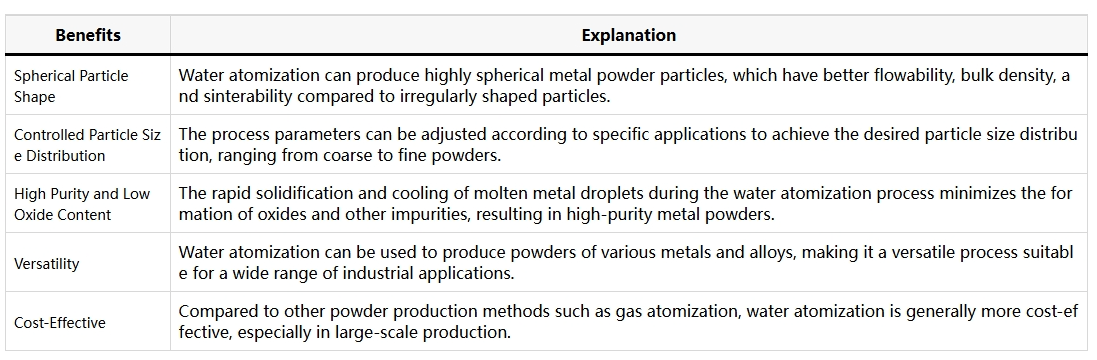

The water atomization process is widely used to produce metal powders with specific particle size distributions, morphologies, and chemical compositions for various applications. By adjusting process parameters such as water pressure, metal flow rate, and nozzle design, the characteristics of the metal powder produced can be controlled.

Water atomization is particularly suitable for producing powders of a wide range of metals and alloys, including aluminum, copper, iron, nickel, titanium, and other materials. The spherical particles produced by this process offer advantages in terms of flowability, bulk density, and sinterability, making them ideal for applications such as rapid prototyping, powder metallurgy, and thermal spraying.

The metal powder water atomization process consists of several key steps:

Melting: The metal or alloy is melted in a furnace, typically an induction furnace or vacuum induction melting furnace (VIM), to achieve the desired temperature and chemical composition.

Pouring: The molten metal is poured through a small-diameter nozzle, which is usually made of refractory materials such as ceramic or tungsten, to control the flow rate and flow diameter.

Atomization: As the molten metal stream exits the nozzle, it encounters high-pressure water jets strategically arranged around the nozzle. The water jets strike the molten metal stream, causing it to break into small droplets due to the high kinetic energy and cooling effect of the water.

Solidification: The atomized droplets rapidly solidify into spherical particles under the cooling effect of the water. The cooling rate and solidification behavior of the particles depend on the metal composition, particle size, and water temperature.

Collection: The solidified metal powder particles are collected together with water into a collection tank or chamber. The water is usually recycled, while the powder is separated and dried for further processing or use.

Depending on the specific nozzle design and water jet configuration, the water atomization process can be further divided into different techniques, such as free-fall water atomization, closed water atomization, and near-coupling water atomization.

Recommend